In the world of modern plastics manufacturing, efficiency, precision, and scalability are paramount. One of the most effective systems used to meet these demands is the 3 Station Mould, or as it’s spelled in American English, the 3 Station Mold. This advanced tool setup is widely used in the thermoforming industry to enhance productivity, reduce cycle times, and improve product quality. In this article, we’ll dive deep into what a 3 Station Mould / 3 Station Mold is, how it works, the benefits it offers, and the industries that rely on this technology for mass production.

What is a 3 Station Mould / 3 Station Mold?

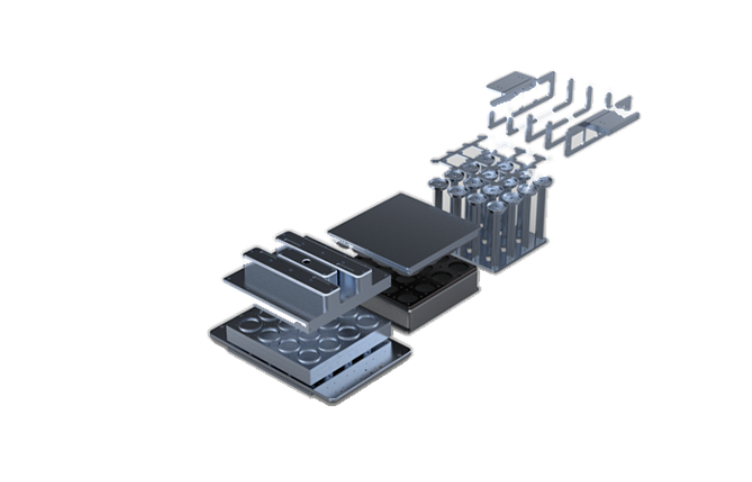

A 3 Station Mould or 3 Station Mold refers to a thermoforming tooling configuration that incorporates three sequential stations within a single production line. These three stations typically include:

Heating Station

Forming Station

Cutting or Trimming Station

This system is designed to streamline the entire thermoforming process by integrating these three steps into one continuous operation. Instead of moving a single plastic sheet through multiple, separate machines, the 3 station setup performs the entire operation in a synchronized cycle. This configuration drastically improves efficiency, especially for high-volume manufacturing.

How Does a 3 Station Mold Work?

1. Heating Station

In the first station, a plastic sheet is fed into the system and heated until it reaches its forming temperature. Uniform heating is critical at this stage to ensure the plastic becomes pliable without overheating or deforming prematurely.

2. Forming Station

Once the sheet is properly heated, it moves to the forming station. Here, it is shaped into the desired product using a 3 Station Mould / 3 Station Mold. This shaping may be done via vacuum forming, pressure forming, or a combination of both. The mold precisely defines the geometry and texture of the final product.

3. Cutting / Trimming Station

Finally, the product enters the third station where excess material is trimmed away. This could involve steel rule dies, punch presses, or CNC trimming. The part is then ready for stacking, packing, or post-processing.

Key Advantages of a 3 Station Mould / 3 Station Mold

1. Enhanced Production Efficiency

By integrating three major production phases into one streamlined operation, cycle times are greatly reduced. Manufacturers can produce large quantities of parts in less time compared to single-station systems.

2. Consistent Product Quality

The automation and synchronization of each station ensure consistent forming conditions, reducing defects and maintaining tight tolerances.

3. Labor Cost Reduction

Fewer manual operations mean less human intervention, which reduces labor costs and lowers the risk of human error.

4. Material Savings

Efficient trimming and controlled heating lead to less waste and better material utilization.

5. Versatility in Design

The system allows for flexibility in product shapes, sizes, and materials. It supports rapid changeover for different molds, making it ideal for both short and long production runs.

Applications of 3 Station Mold Systems

The 3 Station Mould / 3 Station Mold setup is used across various industries due to its high-speed production capabilities:

– Food Packaging

Used to manufacture disposable containers, cups, lids, trays, and blister packs.

– Automotive

Ideal for producing interior panels, liners, trays, and protective covers.

– Medical and Pharmaceutical

Used in forming sterile packaging and medical device components with high precision.

– Consumer Goods

Helps manufacture parts for electronics, appliances, and cosmetics packaging.

Material Compatibility

A wide range of thermoplastic materials can be used with 3 station systems, including:

PET (Polyethylene Terephthalate)

PP (Polypropylene)

PS (Polystyrene)

PVC (Polyvinyl Chloride)

ABS (Acrylonitrile Butadiene Styrene)

These materials can be processed efficiently using custom-designed 3 Station Mould / 3 Station Mold configurations.

Design Considerations for 3 Station Moulds

When designing a 3 Station Mold system, several factors must be considered:

Precision of mold geometry

Proper ventilation and vacuum design

Thermal management of the tooling

Ease of maintenance and cleaning

Integration with automated handling systems

Properly engineered tooling ensures not only high performance but also long-term durability.

The 3 Station Mould / 3 Station Mold is a cornerstone of efficient and scalable thermoforming. Its ability to combine heating, forming, and trimming into a seamless process makes it an invaluable asset for manufacturers aiming to meet high demand with speed and accuracy. As industries continue to push for leaner, more automated production lines, 3 station systems remain a key technology driving innovation and profitability.

Whether you’re in packaging, automotive, medical, or consumer goods, investing in a well-designed 3 Station Mold setup can yield significant returns in terms of quality, throughput, and cost savings.